HVAC Central Systems & Condenser Unit Guide

What is a condenser?

- Condenser fan blade

- Condenser motor

- Condenser coils(fig.1.2)

- Air conditioner compressor is within the condenser unit, but it does not help with heat rejection!

- Fin and tube condensers

- Plate condensers

What’s inside

How coil works

Air conditioner: How does it work?

How the furnace works

What’s inside

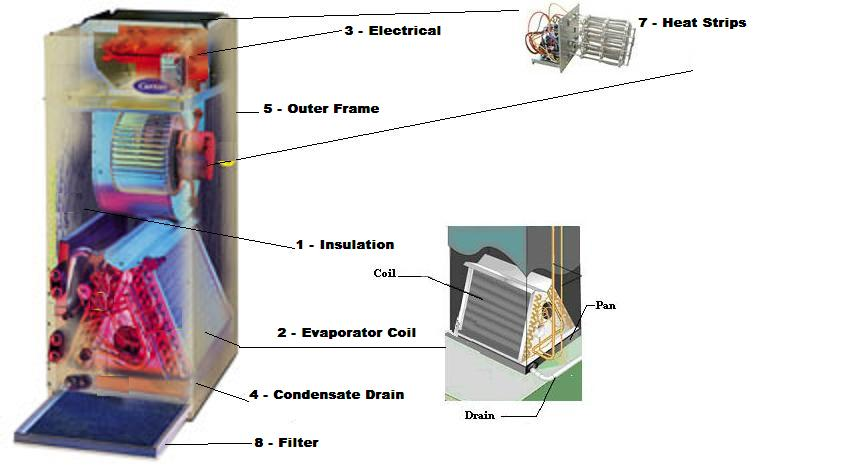

Air handler

Air handlers operate in conjunction with an air conditioning or heat pump system, are simple to the naked eye and are generally used instead of a furnace. An air handler is a box made of sheet metal, with holes on each side and a fan that circulates the air. It also houses essential air conditioning parts, such as an evaporator coil and an air conditioning filter.

There are various sizes and efficiency ratings of air handlers , mainly due to the different air conditioning systems . Both are matched together to provide the very best central air conditioning for the size of the home or office building. Basically, it’s the part of the air conditioning system that solely focuses on the cooling of the house, while the condensing unit, or “outdoor unit,” focuses on the heating. Both have the same parts yet concentrate on different functions to provide both heating and air conditioning.